SALT SPRAY CORROSION TESTS

MaterialScan provides salt spray corrosion tests on anticorrosion coatings and surface treatments for many industrial sectors.

We provide the Italian market as the national contact point of Cotec Labs, a global test center in the field of corrosion and surface analysis and laboratory approved by OEMs like Volvo, Scania, Ford and Daimler.

What do we offer?

More than 300 tests in a catalogue. Laboratory accredited to ISO/IEC 17025 with 15 test cabinets for salt spray corrosion tests and cyclic corrosion tests aiming at guaranteeing quality results and no waiting time.

Support for test method selection. At no additional cost, we provide assistance in selecting the correct test method based on OEM requirements and during the Production Part Approval Process (PPAP).

The laboratory is included in the list approved by OEMs like Volvo, Scania, Ford and Daimler.

The only laboratory in Europe acknowledged by IKEA for salt spray corrosion tests.

Cyclic corrosion testing of large components. The test cabinets can accommodate products of all sizes, not just standardized specimens.

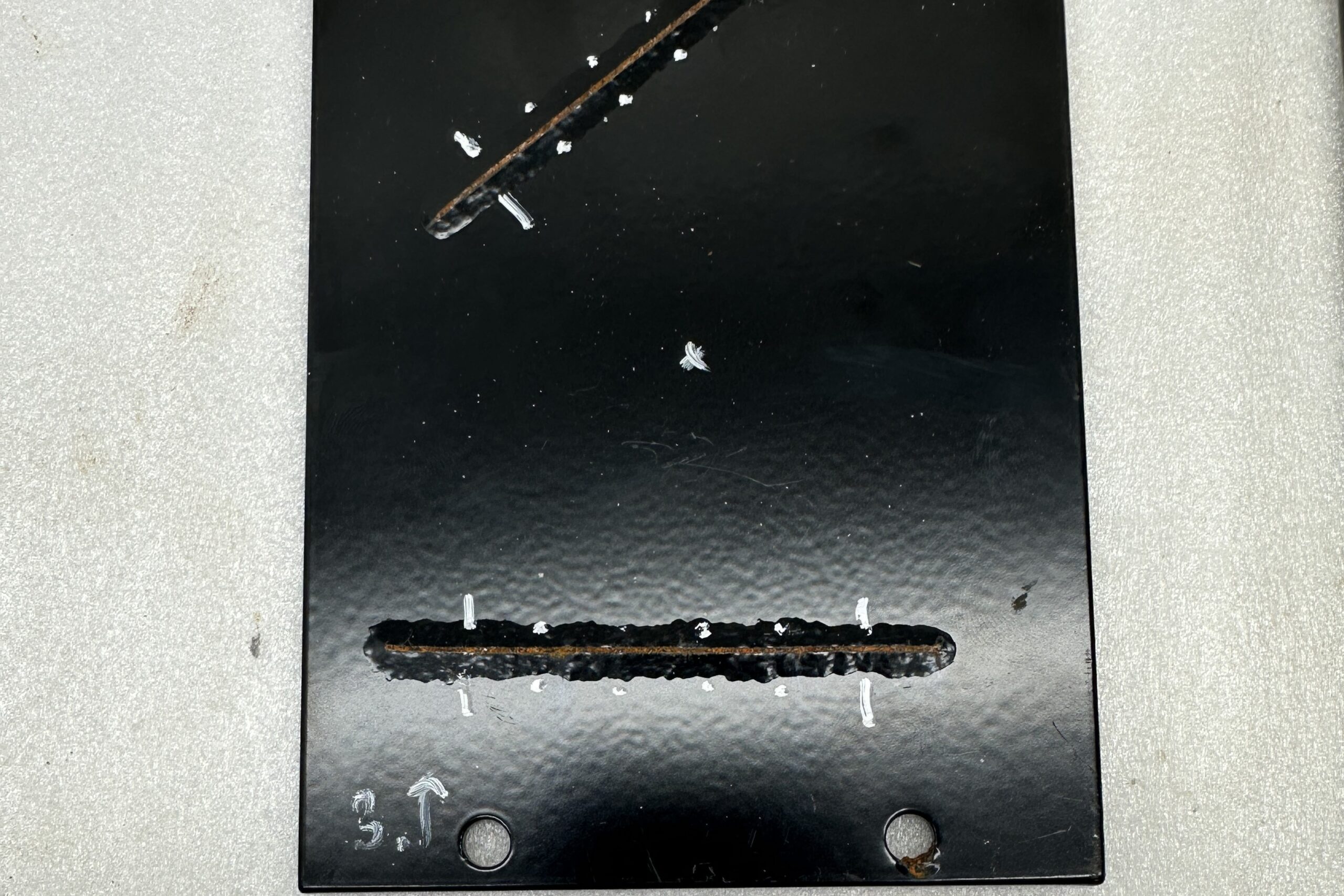

Coating evaluation: degradation, thickness measurement, adhesion, hardness, water-jet and stone chip resistance, chemical resistance.

“Zero-thoughts formula”. Send us your samples, we’ll take care of the rest!

Laboratory for salt spray corrosion tests

Thanks to a 1200 m² climate-controlled laboratory and the fastest lead time on the market, we can satisfy customer requests belonging to the mechanical supply chain of automotive, furniture and building sectors.

In addition to corrosion tests, the laboratory performs tests on anticorrosion surface treatments (paints, varnishes and galvanic coatings) and environmental tests on electrical and electronic components.

Failure analysis and inspections

Our team analyzes failures of plastic or metal components to determine the causes of damage and identify corrective actions.

We perform video inspections and microscopy analysis on-site to evaluate the presence of defects, signs of degradation or other alterations of products and machinery.

Innovation and research funded projects

Do you have an innovative idea and are you looking for assistance in developing it?

We have been working for many years with companies and research organisations on innovation, sustainability and circular economy.

MaterialScan can support your company in research funding programmes, both from a technical point of view and in writing the funding application.

News

Test on coatings and paints

Test on coatings and paints maintenance plan What test on coatings and paints are useful in drawing up a maintenance plan? How to schedule the time for the first intervention? As suggested by ISO 12944-1, the first maintenance work on coatings is...

Insight: P&E Milano Coating Days 2023

On the 25th and 26th of October 2023, we will be present at the third edition of the P&E Milano Coating Days 2023 at the prestigious "Leonardo da Vinci" Museum of Science and Technology in Milan. The two-day event represents the meeting point for the main Italian...

TEST LIST UPDATE – September 2023

NEW CORROSION TESTS ON ORGANIC COATINGS The new catalogue of corrosion tests is constantly being updated in order to expand the range of opportunities offered to customers in various market sectors such as automotive, furniture, metalworking and shipbuilding. Many...